Steam Products

STEAM PRODUCTS & SERVICES

We provide high-performance steam solutions designed to enhance energy efficiency, optimize system performance and reduce operational costs. From steam traps to complete system assessments, our products and services help industries maximize uptime, reduce energy waste and improve process reliability.

If your facility is experiencing steam system performance issues, it may be a sign of inefficiencies that are increasing energy costs, causing unnecessary wear on equipment and leading to frequent downtime. Addressing these issues with a Steam Trap Survey or Steam System Assessment can help restore efficiency and prevent costly failures.

Comprehensive Steam Solutions +

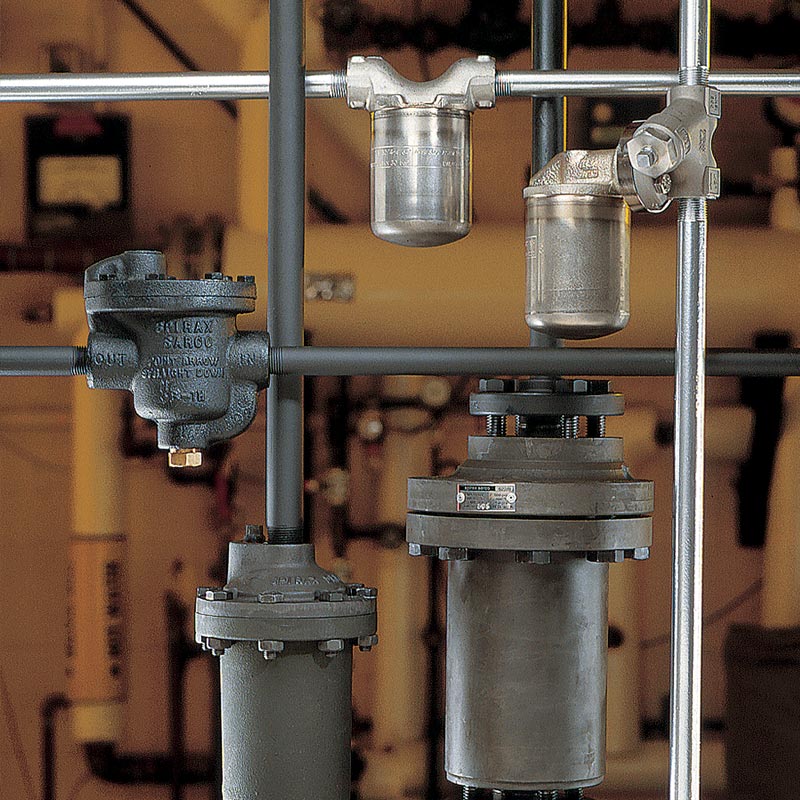

In a steam system, various steam products and components are employed to facilitate the generation, distribution and control of steam for industrial processes and heating applications. These include steam valves for flow and pressure control, steam traps to remove condensate and maintain steam quality, steam piping for distribution, heat exchangers to transfer thermal energy, regulators for pressure management and steam meters for precise measurement.

Our inventory features steam system components built to withstand the most demanding industrial environments. Whether you need pressure control, condensate management or heat recovery, we offer reliable solutions for a safer, more efficient operation.

- Steam Traps and Steam Trap Monitoring

- Pressure Regulators

- Steam Separators

- Pumps and Control Valves

- Complete Steam System Solutions

Recognize Warning Signs in Your Steam System +

A Steam Trap Survey or Steam System Assessment can pinpoint inefficiencies and provide targeted solutions to improve energy efficiency, reduce maintenance costs and extend equipment lifespan. Our expert team will identify problem areas and recommend high-quality steam products to ensure long-term reliability and peak performance.

Common steam system issues:

- Unusual noises – Knocking, banging or pinging sounds in the steam pipes.

- Slow startup – Steam system takes too long to reach operating temperature.

- Pipe movement or vibration – Unstable steam flow, causing pipes to shake.

- Inefficient heat transfer – Heat exchangers are slow to warm up or struggle to maintain temperature.

- Frequent valve replacements – Steam system valves are wearing out too quickly.

- Condensate drainage issues – Tanks or kettles cannot heat properly without draining condensate first.

- Excessive flash steam discharge – Steam vents, condensate return tanks or roof vents are releasing too much steam.

- Rising boiler makeup water consumption – Increasing demand for fresh water indicates inefficiencies.

- Frequent motor replacements – Electric condensate pump skid motors are failing too often.

- Unexplained energy costs – A sudden increase in the natural gas bill without any apparent cause.

- Download our Steam Troubleshooting Guide (PDF)

Manufacturers:

- SPIRAX SARCO

- Warren Controls

Main Industries/Sectors:

- Food and Beverage Manufacturing

- Pharmaceutical

- Oil, Petrochemical and Chemical—Refineries, Oil Production and Chemical Manufacturing

- Institutions—Hospitals, Universities, Prisons, etc.

- Steam Trap Surveys

- Steam System Assessment